On-Site Steel Reinforcement Installation: The Key to Structural Integrity

Wiki Article

Specialist Steel Repairing Solutions for Strong and Resilient Frameworks

The role of expert steel taking care of remedies is crucial in the building of strong and sturdy frameworks, as they make certain the specific positioning and safe fastening of support bars. Recognizing the key advantages and possible challenges connected with steel taking care of can dramatically affect project results.Importance of Steel Fixing

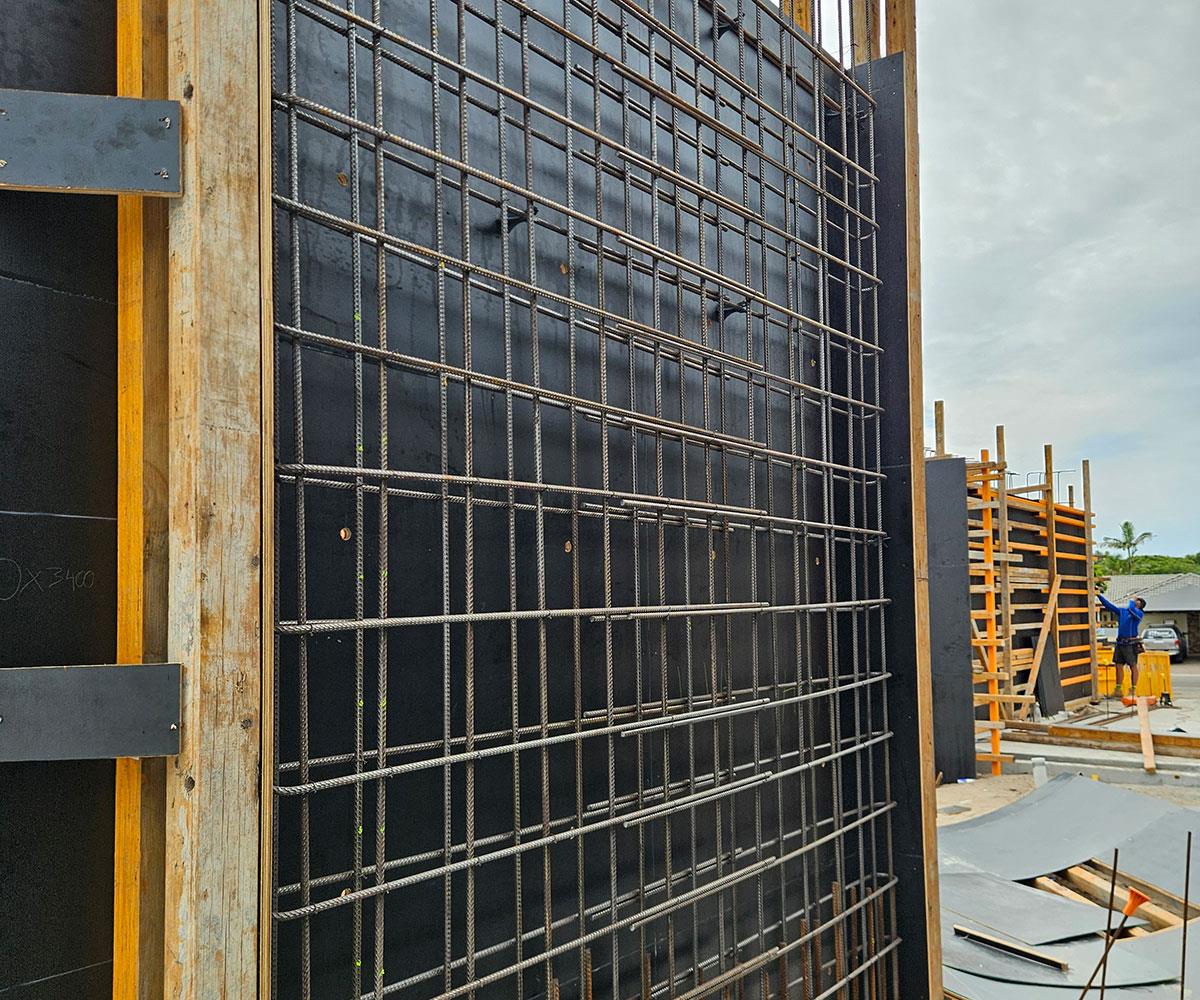

Steel dealing with is essentially essential in the building and construction sector, as it guarantees the architectural stability and sturdiness of reinforced concrete elements. The procedure involves the cautious placement and binding of steel support bars (rebar) within concrete, which substantially enhances the load-bearing ability and resistance to tensile forces. Without appropriate steel fixing, concrete frameworks are vulnerable to splitting, working out, and inevitably failure under used loads, bring about potential threats and costly repairs.In addition, steel repairing adds to the total design versatility, permitting designers and designers to create complicated structures that satisfy details functional and aesthetic needs. The use of steel reinforcement not just increases the life expectancy of concrete aspects yet also lowers upkeep costs in time, making it a sensible financial investment for any type of building job.

Furthermore, adherence to industry standards and guidelines in steel dealing with practices makes sure conformity with safety and security protocols, thus securing both employees on-site and future passengers of the framework. In amount, the significance of steel taking care of expands past plain building and construction; it plays a crucial role in enhancing efficiency, durability, and safety, solidifying its standing as a vital element of modern building techniques.

Key Techniques in Steel Repairing

Reliable steel dealing with counts on a selection of strategies that improve the security and efficiency of reinforced concrete frameworks. One essential method is the precise placement of rebars, guaranteeing that they are positioned according to comprehensive layout specs. This includes sticking to proper cover demands to safeguard steel from corrosion and preserve structural stability.

Proper welding and mechanical couplers are likewise important in signing up with rebar sectors, providing a continuous tons course throughout the structure - steel fixing. The selection of couplers have to be lined up with job requirements to assure ideal stamina

Finally, extensive examination and quality assurance throughout the steel repairing procedure are important. Regular checks should be performed to validate that all techniques are executed properly, making sure that the final structure follows safety requirements and design requirements. These essential methods collectively add to the general toughness and durability of strengthened concrete constructions.

Benefits of Expert Steel Correcting

When taking into consideration building and construction projects, one can not ignore the substantial benefits of using professional steel repairing services. Firstly, expert steel fixers possess specialized knowledge and skills that guarantee the exact installation of steel support. This competence straight adds to the structural honesty of structures, bridges, and other facilities, inevitably boosting security and longevity.Moreover, specialist steel fixing services stick to sector requirements and regulations, minimizing the dangers of non-compliance. This not just secures the project from possible legal issues yet also guarantees that the building and construction satisfies security benchmarks. Furthermore, experienced steel fixers utilize sophisticated methods and tools, which leads to enhanced performance in the building and construction procedure. This efficiency can equate to cost savings and prompt task completion.

Typical Difficulties and Solutions

In building jobs, different difficulties can develop during the steel repairing process, impacting both timelines and structural quality. One common issue is the imbalance of steel bars, which can cause architectural weak points and necessitate rework. To alleviate this, routine inspections and specific measurements must be conducted throughout the setup phase.Another challenge is the possibility for deterioration, specifically in settings with high dampness or exposure to chemicals. Making use of corrosion-resistant products and applying safety finishes can dramatically expand the life-span of the steel framework. In addition, making certain appropriate drainage can help decrease water build-up.

Labor shortages and ability spaces in the workforce present another difficulty, commonly leading to hold-ups and inconsistent quality. Purchasing training programs and using skilled professionals can improve the ability of the team and enhance total effectiveness.

Lastly, website constraints, such as restricted access or space, can complicate the steel repairing process. steel fixing. Using modular building and construction methods or prefabrication can alleviate these issues by permitting elements to be set up off-site, thus simplifying the installation process

Attending to these challenges with proactive solutions ensures that the steel taking care of procedure adds positively to the job's success.

Future Trends in Steel Dealing With

As the construction industry remains to develop, the future of steel taking care of is poised to welcome ingenious innovations and approaches that improve effectiveness and safety and security. One substantial fad is the integration of automation and robotics in steel fixing procedures. Automated systems can streamline the placement and tying of rebar, minimizing labor costs and lessening human error.Additionally, innovations in Structure Details Modeling (BIM) are transforming how steel repairing is intended and implemented (steel fixing). BIM permits specific visualization of structural parts, promoting much better control amongst different trades and ensuring exact installation of support products

Sustainability is also becoming a key focus in steel repairing practices. The use of high-strength, light-weight products and environmentally friendly finishings is expected to climb, contributing to decreased product waste and power usage.

In addition, the adoption of wise innovations, such as sensors and IoT tools, will certainly allow real-time monitoring of structural stability. This proactive approach to maintenance will improve the long life of structures and boost safety and security criteria.

Final Thought

Finally, specialist steel repairing solutions are vital for the stability and durability of strengthened concrete structures. The application of advanced techniques and adherence to industry standards significantly enhances load-bearing capacity and resistance to tensile forces. In addition, addressing common difficulties through innovative approaches promotes resilience in constructed atmospheres. As the area develops, continued advancements in steel taking care of techniques will additionally contribute to the growth of more secure, much more resilient infrastructure, eventually benefiting society as a whole.The duty of steel fixing contractors melbourne specialist steel repairing remedies is crucial in the building of strong and resilient structures, as they make sure the accurate placement and protected fastening of support bars.Steel taking care of is fundamentally critical in the construction market, as it makes sure the structural integrity and resilience of reinforced concrete aspects. Expert steel fixers possess specialized expertise and abilities that make certain the accurate installation of steel reinforcement. In recap, the benefits of professional steel taking care of variety from enhanced architectural honesty to conformity with regulations, making it a very useful part of successful construction tasks.

As the construction industry proceeds to advance, the future of steel fixing is positioned to welcome innovative technologies and techniques that improve efficiency and safety.

Report this wiki page